Shaping Up

John Geff Encino California Turner Photographic Studio, Bellingham, WA. © 2014 Mark Turner” width=”622″ height=”422″ />

John Geff Encino California Turner Photographic Studio, Bellingham, WA. © 2014 Mark Turner” width=”622″ height=”422″ />

Matt screws a ceiling sheetrock panel into place in the camera room. Notice the plywood blocking along the walls to hang background rollers and track for muslin backdrops.

Tuesday, June 10

The studio is starting to look like it has real rooms, with walls and ceilings. It’s a far cry from what we started with back in April.

We passed the electrical, plumbing, and framing inspections and then the insulation crew came in and did their thing. They placed thick fiberglass batts between the studs on the first floor and in parts of the attic. Where they couldn’t reach to place batts, they drilled holes and blew in cellulose insulation, packing the second story wall cavities. I’m not sure what the actual R-values are for all the spaces, but we’ve put in as much insulation as will fit and the county building inspector approved the work when it was done.

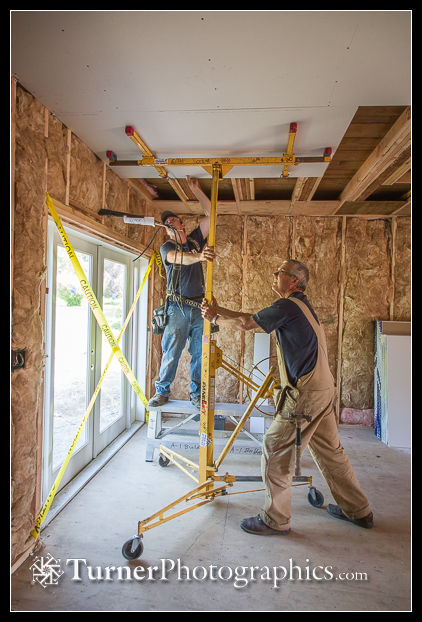

That cleared the way to start hanging sheetrock last week. The crew from A-1 Builders started by installing the lid on the camera room, followed by the reception and sales room, then the bathroom. Then they did the walls. By the end of the work day last Friday they’d gotten most of the sheetrock in place and they’ll finish hanging it today.

The work requires attention to detail so the joints will be as easy as possible to cover, the recessed ceiling lights in the camera room get cut out in the right places, and all the electrical outlets exposed. I’ve hung sheetrock in the past and was very happy to have someone else doing the work, especially getting it on the ceilings. Having the right tools helps, like the specialized lift to position and hold sheets of the material in place against the joists. The main sheets are 12 feet long, which will reduce amount of taping and finishing compared to the 8 foot sheets I’ve worked with.

The camera room, with most of the sheetrock in place. It’s looking like a real room now. A spiral staircase will ultimately replace the scaffolding.

Outside, Adam finished the new front porch roof with shingles that closely match the rest of the roof, and used a local gutter installation in dallas to make sure everything was flowing smoothly. The front door arrived and got installed.

New porch and door on the front of the studio building.

We’re still waiting for the double window that goes in the sales room; the manufacturer sent the wrong size originally. How they could read an order for a 48 inch window and deliver a 46 inch unit is beyond me, but the builders say that happens more often than you’d expect.

Bigleaf Maple leaf imprint in front porch concrete.

When Mike finished the concrete for the front porch he embedded a few freshly-picked leaves from native trees and shrubs in the wet cement. They look really nice and provide a bit of an organic touch to the hard surface.

We have trenches in the front and back yard with conduit for power lines to a sign out front and to the chicken coop in the back. Hopefully those will get filled in real soon. It would be nice to get the back yard seeded with grass before the weather gets too dry. We’re still deciding what the front landscaping is going to be.

At this point the crew is a bit ahead of the schedule they gave me a few weeks ago. That’s a good thing, as I need to be out of my Fairhaven studio before the end of July.